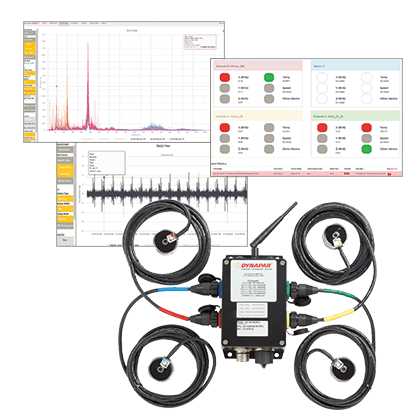

Cut costs and boost productivity with a condition-monitoring tool designed for ease of use and scalability. The Dynapar OnSite™ system is a powerful predictive maintenance system targeted at preventing failures before they occur. It can slash unscheduled downtime, improve the efficiency of route-based vibration analysis, and provide real-time analytics and trending to warn of possible machine failures.

Get Started with Affordable Remote Condition Monitoring Today!

Get Started with Affordable Remote Condition Monitoring Today!Discover the powerful analytical tools of the Dynapar OnSite™ System. Please fill out the form to receive a brochure and datasheet with product specifications, a guided tour of the analysis tools and a free demo of the OnSite system if your application qualifies.

“The bearing didn't go into catastrophic failure. The customer didn't have to shut down the plant in the middle of the day. The vibration data from the OnSite system helped us find and diagnose the problem early.”

“The bearing didn't go into catastrophic failure. The customer didn't have to shut down the plant in the middle of the day. The vibration data from the OnSite system helped us find and diagnose the problem early.”

- Predictive Maintenance Manager, Working with a Major US Food Manufacturer

© Copyright Dynapar 2022 All Rights Reserved